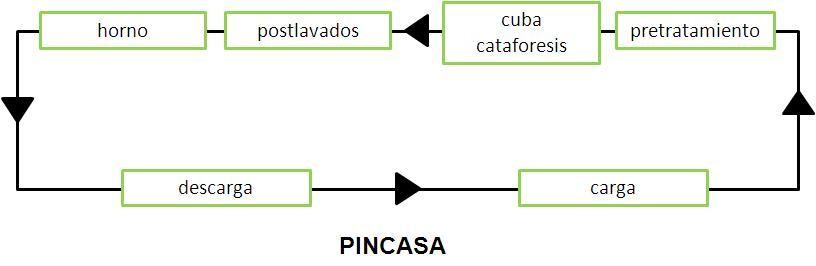

Pretratamientos: Limpia, desengrasa y prepara la superficie mediante un proceso de conversión.

Pretreatment: Clean, degrease and prepare the surface by a conversion process.

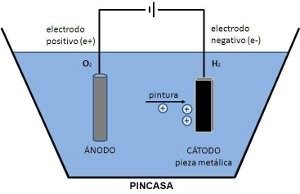

Cataphoresis Bath: In this bath the paint is applied by electroplating process. The bath consists of deionized water at 80% -90% and paint solids (resins and pigments) at 10% -20%. Resin is the main component of the final layer and provides corrosion resistance and durability. The pigments are used to provide the black color and brightness. During this process the layer of paint applied can vary by adjusting the applied voltage. E-coat is epoxy type paint.

Post washes: In these washes the parts are rinsed to remove paint solids that may have been dragged. Excess paint is returned to the cata bath to improve application efficiency

Curing Oven: The layer of paint applied over parts cure during more than 20 minutes at 180 º C

The following gallery shows the process from a part is unpacked until it is packed again and ready for delivery to the customer.